| APPLICATIONS |

|

| USE |

|

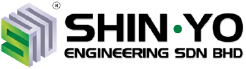

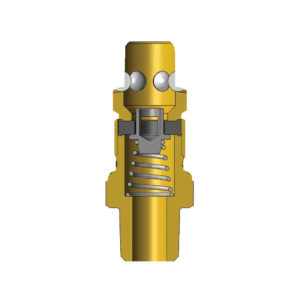

| CONSTRUCTIONS |

|

| SIZE | PLATED STEEL PART # | 316 STAINLESS STEEL PART # | ALUMINUM PART # |

| 1/2″ | STB1 | – | – |

| 3/4″ | STB5 | RSTB5 | – |

| 1″ | STB10 | RSTB10 | ASTB10 |

| 1 1/4″ | STB15 | RSTB15 | ASTB15 |

| 1 1/2″ | STB20 | RSTB20 | ASTB20 |

| 2″ | STB25 | RSTB25 | ASTB25 |

| 2 1/2″ | STB30 | RSTB30 | ASTB30 |

| 3″ | STB35 | RSTB35 | ASTB35 |

| 4″ | STB40 | RSTB40 | ASTB40 |

| 5″ | STB50 | – | ASTB50 |

| 6″ | STB60 | RSTB60 | ASTB60 |

| 8″ | STB80 | RSTB80 | ASTB80 |

| 10″ | STB100 | – | ASTB100 |

| 12″ | STB120 | – | – |

*King Combination Nipples are not recommended for steam

*The working pressure may vary with the construction of the hose, the type clamping system used and the application. Consult us for recommendations

*In accordance with the R.M.A bulletin for oil suction and discharge hose, a coupled length of hose in any size, should be tested to 1-1/2 times the working pressure and held for fifteen minutes without leaking or coupling movement. For additional information and detailed instruction on testing procedures, see the Rubber manufactures Association (R.M.A) handbook

*Not for compressible products such as air or nitrogen

WARNING: Cancer and Reproductive Harm

| Weight | N/A |

|---|---|

| Size | 1/2", 3/4", 1", 1 1/4", 1 1/2", 2", 2 1/2", 3", 4", 5", 6", 8", 10", 12" |

| Material | Plated Steel Part, 316 Stainless Steel, Aluminum Part |

Be the first to review “King™ Combination Nipples Beveled End” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.