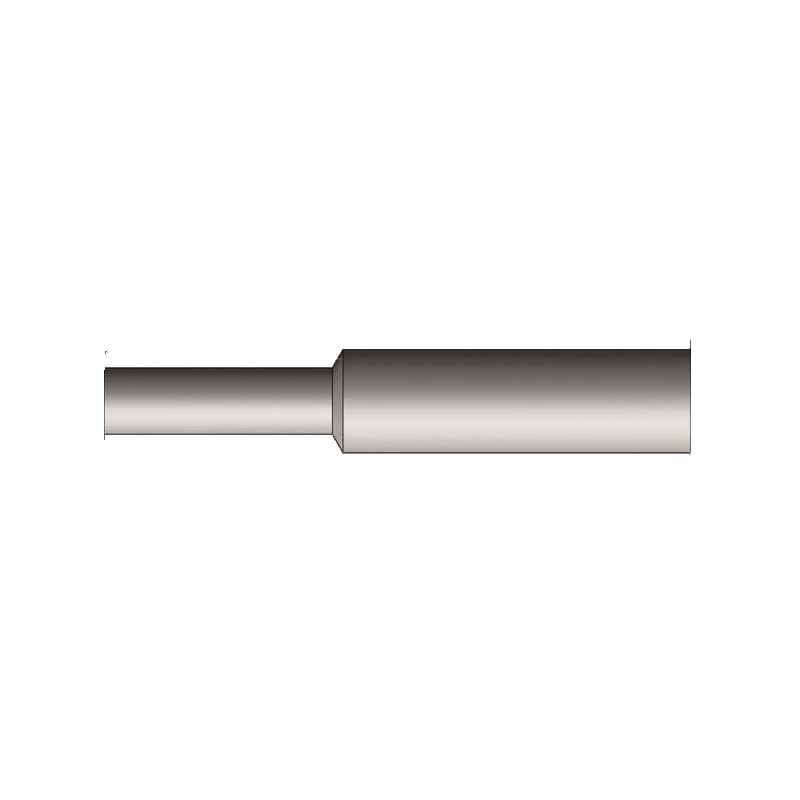

DF-Series Industrial Interchange Nipple (Male Threads)

RM7.50 – RM102.50

| SPECIFICATION | • Rated pressure when connected with Brass D-Series Automatic Couplers: 500 PSI (35 bar) Maximum Working and 16,000 PSI (1,100 bar) Burst • Rated pressure when connected with Brass F-Series Manual Couplers: 500 PSI (35 bar) Maximum Working and 11,500 PSI (790 bar) Burst • Rated pressure when connected with Steel F-Series Manual Couplers: 500 PSI (35 bar) Maximum Working and 6,500 PSI (448 bar) Burst |

| CONSTUCTION | • Machined components are manufactured using solid bar stock. • Steel componentry is plated using ROHS Compliant Trivalent Chrome. |

| COMPATIBILITY & INTERCHANGE DATA |

• Foster 3, 4, 5 and 6 Series • Parker 30- Series Automatic Interchange & Parker 20-Series Manual Interchange • Hansen 3000, 4000, 5000 and 6000 & Hansen 1000, 400 and 500 |

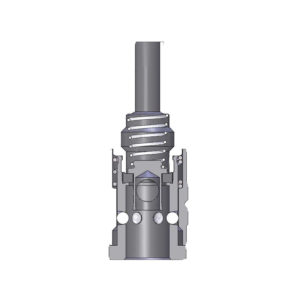

| HOW IT WORKS | • To disconnect, begin by holding the hose on the nipple side with three of your fingers, leaving your thumb and index finger free. • Grab the sleeve with your thumb and index finger and begin to pull the sleeve towards the palm of your hand. • After pulling the sleeve, the nipple will move out of the coupler slightly. Continue to hold the hose and coupler sleeve until all air is fully exhausted. • After the line is fully exhausted, you are able to safely separate the nipple from the coupler |

| SIZE | PART NUMBER | THREADS | MATERIAL | LENGTH | Maximum OD | HEX Inch | Weight Lb | ||

| inch | mm | inch | mm | ||||||

| 1/4″ | D2M1 | 1/8” – 27 NPTF | Steel | 1.57 | 39.9 | 0.58 | 14.7 | 1/2″ | 0.05 |

| 1/4″ | D2M1-B | 1/8” – 27 NPTF | Brass | 1.57 | 39.9 | 0.58 | 14.7 | 1/2″ | 0.05 |

| 1/4″ | D2M1-S | 1/8” – 27 NPTF | 303 Stainless | 1.57 | 39.9 | 0.58 | 14.7 | 1/2″ | 0.05 |

| 1/4″ | D2M2 | 1/4” – 18 NPTF | Steel | 1.69 | 42.9 | 0.65 | 16.5 | 9/16″ | 0.05 |

| 1/4″ | D2M2-B | 1/4″ – 18 NPTF | Brass | 1.69 | 42.9 | 0.65 | 16.5 | 9/16″ | 0.05 |

| 1/4″ | D2M2-S | 1/4” – 18 NPTF | 303 Stainless | 1.69 | 42.9 | 0.65 | 16.5 | 9/16″ | 0.06 |

| 1/4″ | D2BM2 | 1/4” – 19 BSPT | Steel | 1.69 | 42.9 | 0.65 | 16.5 | 9/16″ | 0.05 |

| 1/4″ | D2M3 | 3/8” – 18 NPTF | Steel | 1.75 | 44.5 | 0.79 | 20.1 | 11/16″ | 0.05 |

| 1/4″ | D2M3-B | 3/8” – 18 NPTF | Brass | 1.75 | 44.5 | 0.79 | 20.1 | 11/16″ | 0.07 |

| 1/4″ | D2M3-S | 3/8” – 18 NPTF | 303 Stainless | 1.75 | 44.5 | 0.79 | 20.1 | 11/16″ | 0.08 |

| 1/4″ | D2BM3 | 3/8” – 19 BSPT | Steel | 1.75 | 44.5 | 0.79 | 20.1 | 11/16″ | 0.07 |

| 3/8″ | D3M2 | 1/4” – 18 NPTF | Steel | 1.81 | 46.0 | 0.79 | 20.1 | 11/16″ | 0.08 |

| 3/8″ | D3M3 | 3/8” – 18 NPTF | Steel | 1.87 | 47.5 | 0.79 | 20.1 | 11/16″ | 0.09 |

| 3/8″ | D3M3-B | 3/8” – 18 NPTF | Brass | 1.87 | 47.5 | 0.79 | 20.1 | 11/16″ | 0.09 |

| 3/8″ | D3M3-S | 3/8” – 18 NPTF | 303 Stainless | 1.87 | 47.5 | 0.79 | 20.1 | 11/16″ | 0.09 |

| 3/8″ | D3BM3 | 3/8” – 19 BSPT | Steel | 1.87 | 47.5 | 0.79 | 20.1 | 11/16″ | 0.09 |

| 3/8″ | D3M4 | 1/2” – 14 NPTF | Steel | 2.03 | 51.6 | 1.01 | 25.7 | 7/8″ | 0.15 |

| 1/2″ | D4M2 | 1/4” – 18 NPTF | Steel | 2.13 | 5.41 | 0.79 | 20.1 | 11/16″ | 0.14 |

| 1/2″ | D4M3 | 3/8” – 18 NPTF | Steel | 2.19 | 55.6 | 0.79 | 20.1 | 11/16″ | 0.16 |

| 1/2″ | D4M4 | 1/2” – 14 NPTF | Steel | 2.34 | 59.4 | 1.01 | 25.7 | 7/8″ | 0.16 |

| 1/2″ | D4M4-B | 1/2” – 14 NPTF | Brass | 2.34 | 59.4 | 1.01 | 25.7 | 7/8″ | 0.18 |

| 1/2″ | D4M4-S | 1/2” – 14 NPTF | 303 Stainless | 2.34 | 59.4 | 1.01 | 25.7 | 7/8″ | 0.16 |

| 1/2″ | D4BM4 | 1/2” – 14 BSPT | Steel | 2.34 | 59.4 | 1.01 | 25.7 | 7/8″ | 0.16 |

| 1/2″ | D4M6 | 3/4” – 14 NPTF | Steel | 2.50 | 63.5 | 1.23 | 31.2 | 1 1/16″ | 0.24 |

| 1/2″ | D4M6-B | 3/4” – 14 NPTF | Brass | 2.50 | 63.5 | 1.23 | 31.2 | 1 1/16″ | 0.24 |

| 3/4″ | D6M4 | 1/2” – 14 NPTF | Steel | 2.38 | 60.5 | 1.52 | 38.6 | 1 5/16″ | 0.22 |

| 3/4″ | D6M6 | 3/4” – 14 NPTF | Steel | 2.38 | 60.5 | 1.52 | 38.6 | 1 5/16″ | 0.25 |

| 3/4″ | D6M8 | 1”- 11 1/2” NPTF | Steel | 2.56 | 65.0 | 1.80 | 45.7 | 1 9/16″ | 0.26 |

*It is important to be safe when installing quick disconnect couplings into a pneumatic circuit. Never install a pneumatic coupling directly into an air tool, use a piece of hose that is at least 18″ long, between the tool and the coupling, to prevent damage to the coupling. To protect the operator, safety devices, such as a safety check valve and safety cable should be installed in case there is a hose or coupling failure.

WARNING: Cancer and Reproductive Harm

| Weight | 1 kg |

|---|---|

| Size | 1/4", 3/8", 1/2", 3/4" |

| Part Number | D2M1, D2M1-B, D2M1-S, D2M2, D2M2-B, D2M2-S, D2BM2, D2M3, D2M3-B, D2M3-S, D2BM3, D3M2, D3M3, D3M3-B, D3M3-S, D3BM3, D3M4, D4M2, D4M3, D4M4, D4M4-B, D4M4-S, D4BM4, D4M6, D4M6-B, D6M4, D6M6, D6M8 |

| Material | Steel, Brass, 303 Stainless |

Be the first to review “DF-Series Industrial Interchange Nipple (Male Threads)” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.