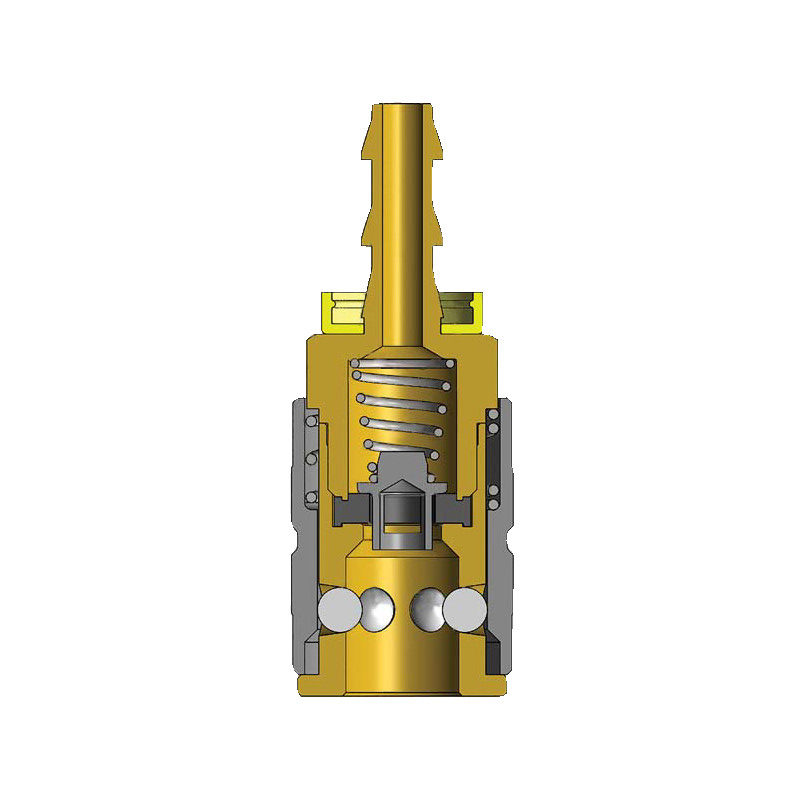

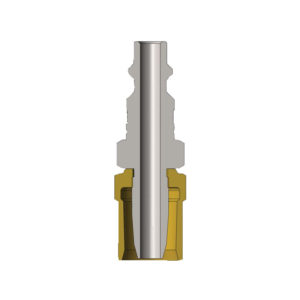

F-Series Manual Industrial Interchange Coupler (Push-Loc Barb)

RM40.00 – RM123.00

| SPECIFICATIONS | • Rated pressure for connected Brass Coupler & Brass Plug: 300 PSI (20 bar) Maximum Working and 8,500 PSI (586 bar) Burst • Rated pressure for connected Brass Coupler & Steel Plug: 500 PSI (35 bar) Maximum Working and 9,000 PSI (620 bar) Burst |

| CONSTUCTION | • Machined components are manufactured using solid bar stock. • Stainless steel balls, retaining rings and springs maximize corrosion resistance and extend service life. • Nitrile (Buna-N) seals are standard • Steel componentry is plated using ROHS Compliant Trivalent Chrome. • Steel sleeve and steel tubular valve |

| COMPATIBILITY & INTERCHANGE DATA |

• Foster 3, 4, 5 and 6 Series • Parker 20-Series Manual Interchange • Hansen 1000, 400 and 500 |

| HOW IT WORKS | • To disconnect, begin by holding the hose on the nipple side with three of your fingers, leaving your thumb and index finger free. • Grab the sleeve with your thumb and index finger and begin to pull the sleeve towards the palm of your hand. • After pulling the sleeve, the nipple will move out of the coupler slightly. Continue to hold the hose and coupler sleeve until all air is fully exhausted. • After the line is fully exhausted, you are able to safely separate the nipple from the coupler |

| SIZE | PART NUMBER | HOSE ID | MATERIAL | LENGTH | Maximum OD | HEX Inch | Weight Lb | ||

| inch | mm | inch | mm | ||||||

| 1/4″ | 2FB2-B | 1/4″ | Brass | 2.49 | 63.2 | 0.88 | 22.4 | 3/4″ | 0.18 |

| 1/4″ | 2FB3-B | 3/8″ | Brass | 2.49 | 63.2 | 0.88 | 22.4 | 3/4″ | 0.19 |

| 3/8″ | 3FB2 | 1/4″ | Steel | 2.80 | 71.1 | 1.06 | 26.9 | 7/8″ | 0.25

|

| 3/8″ | 3FB3 | 3/8″ | Steel | 2.80 | 71.1 | 1.06 | 26.9 | 7/8″ | 0.27 |

| 3/8″ | 3FB4 | 1/2” | Steel | 2.80 | 71.1 | 1.06 | 26.9 | 7/8″ | 0.28 |

| 1/2″ | 4FB3 | 3/8″ | Steel | 3.40 | 86.4 | 1.19 | 30.2 | 1″ | 0.40 |

| 1/2″ | 4FB4 | 1/2” | Steel | 3.40 | 86.4 | 1.19 | 30.2 | 1″ | 0.43 |

*It is important to be safe when installing quick disconnect couplings into a pneumatic circuit. Never install a pneumatic coupling directly into an air tool, use a piece of hose that is at least 18″ long, between the tool and the coupling, to prevent damage to the coupling. To protect the operator, safety devices, such as a safety check valve and safety cable should be installed in case there is a hose or coupling failure.

* Operating pressure for couplings utilizing hose barb connections may be dramatically reduced to that of the hose rating and/or hose end connection combination.

Consult hose manufacturer’s catalog for hose end connection ratings. If in doubt, test under controlled conditions for suitability to application.

* Dixon cannot assume liability for misapplication of production resulting in equipment down-time, lost production, and/or personal injury including death.

WARNING: Cancer and Reproductive Harm

| Weight | 1 kg |

|---|---|

| Size | 1/4", 3/8", 1/2" |

| Part Number | 2FB2-B, 2FB3-B, 3FB2, 3FB3, 3FB4, 4FB3, 4FB4 |

| Material | Brass, Steel |

Be the first to review “F-Series Manual Industrial Interchange Coupler (Push-Loc Barb)” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.