| APPLICATIONS |

|

| USE |

|

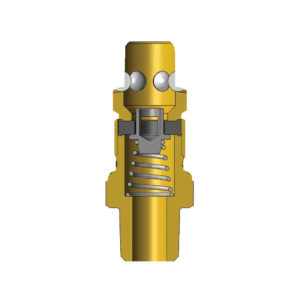

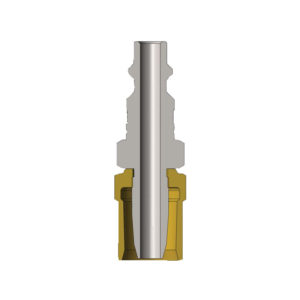

| CONSTRUCTION |

|

| HOSE x NPT SIZE | UNPLATED STEEL PART # | PLATED STEEL PART # | BRASS PART # | ALUMINUM PART # |

| 1 1/4” | – | – | BST15 | AST15 |

| 1 1/2″ | – | – | BST20 | AST20 |

| 2” | – | – | BST25 | AST25 |

| 2 1/2” | ST30 | STC30 | BST30 | AST30 |

| 3” | ST35 | STC35 | BST35 | AST35 |

| 4” | ST40 | STC40 | BST40 | AST40 |

| 5” | ST50 | STC50 | – | AST50 |

| 6” | ST60 | STC60 | – | AST60 |

| 8” | ST80 | STC80 | – | – |

| 10” | ST100 | STC100 | – | – |

| 12” | ST120 | STC120 | – | – |

| HOSE SHANK X NPT | 316 STAINLESS STEEL PART # | HASTELLOY PART # |

| 1/2″ | RST11 | – |

| 3/4” | RST51 | – |

| 1” | RST10 | – |

| 1 1/4” | RST15 | – |

| 1 1/2” | RST20 | – |

| 2” | RST25 | HST25 |

| 2 1/2” | RST30 | – |

| 3” | RST35 | HST35 |

| 4” | RST40 | – |

| 5” | RST50 | – |

| 6” | RST60 | – |

| 8” | RST80 | – |

1Made from investment casting

*King Combination Nipples are not recommended for steam

*The working pressure may vary with the construction of the hose, the type clamping system used and the application. Consult us for recommendations

*In accordance with the R.M.A bulletin for oil suction and discharge hose, a coupled length of hose in any size, should be tested to 1-1/2 times the working pressure and held for fifteen minutes without leaking or coupling movement. For additional information and detailed instruction on testing procedures, see the Rubber manufactures Association (R.M.A) handbook

WARNING: Cancer and Reproductive Harm

| Weight | N/A |

|---|---|

| Hose Shank x NPT | 1/2", 3/4", 1", 1 1/4", 1 1/2", 2", 2 1/2", 3", 4", 5", 6", 8", 10", 12" |

| Material | Unplated Steel Part, Plated Steel Part, Brass Part, Aluminum Part, 316 Stainless Steel Part, Hastelloy Part |

Be the first to review “King™ NPT Threaded End No Knurl” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.