| USE |

|

| SPECIFICATIONS |

|

| FEATURES |

|

| INSTRUCTIONS |

|

| HOSE ID | HOSE OD | ZINC PLATED IRON PART # | STAINLESS STEEL 4 PART # | TORQUE ft. lbs.2 | BRASS PART # | TORQUE | |

| FROM | T0 | ||||||

| 1″ | 1 34/64” | 1 46/64” | BU14 | RBU14 | 21 | BBU14 | 18 |

| 1″ | 1 44/64” | 1 60/64” | B14 | RB14 | 21 | – | – |

| 1″ | 1 60/64” | 2 8/64” | B15 | – | 21 | – | – |

| 1 1/4″ | 1 32/64” | 1 50/64” | BU18 | – | 40 | – | – |

| 1 1/4″ | 1 50/64” | 2 6/64” | BU19 | – | 40 | – | – |

| 1 1/4″ | 2 8/64” | 2 24/64” | B19 | RB19 | 40 | – | – |

| 1 1/2″ | 1 52/64” | 2” | BU22 | – | 40 | – | – |

| 1 1/2″ | 2” | 2 14/64” | B22 | – | 40 | – | – |

| 1 1/2″ | 2 12/64” | 2 24/64” | BU24 | RBU24 | 40 | – | – |

| 1 1/2″ | 2 24/64” | 2 36/64” | B24 | RB24 | 40 | – | – |

| 1 1/2″ | 2 36/64” | 2 48/64” | B25 | – | 40 | – | – |

| 2″ | 2 22/64” | 2 34/64” | BU28 | – | 60 | – | – |

| 2″ | 2 32/64” | 2 50/64” | BU29 | RBU29 | 60 | BBU291 | 40 |

| 2″ | 2 48/64” | 3 4/64” | B29 | RB29 | 60 | – | – |

| 2″ | 3 6/64” | 3 28/64” | B30 | – | 60 | – | – |

| 2 1/2″ | 3 6/64” | 3 28/64” | BU34 | – | 60 | – | – |

| 2 1/2″ | 3 32/64” | 3 60/64” | B34 | – | 150 | – | – |

| 3″ | 3 32/64” | 3 60/64” | BU35 | RBU35 | 150 | – | – |

| 3″ | 3 52/64” | 4 4/64” | B35 | – | 150 | – | – |

| 3″ | 4 4/64” | 4 28/64” | B39 | – | 200 | – | – |

1Will become obsolete as inventory is deplated

2Torque applies to plated iron and stainless steel clamps

3Global investment cast carbon steel

4When installing stainless steel bolts and nuts, the use of anti-seize or anti-galling lubricant is advised. A light coat is required on the bolt threads to prevent thread galling and artificial torque reading

*The bolts used in the Boss interlocking clamps are not standard bolts. The vary from standard bolts. The vary from standard bolts in their length, diameter, overall thread length and material hardness. These bolts bend only. Dixon recommended using only factory supplied replacement bolts. Replacement nuts and blots are available, contact us for more information

*Torque values for clamps are based on dry boils. The use of lubricant on bolts will adversely effect clamp performance. Do not lubricant nuts and bolts. Recommended rating in ft. lbs.

*Worn-out hose couplings can be dangerous. They should be checked regularly and replace when necessary. Each coupling user should review applications and add safety devices where indicated

*Note: Pressurized steam is an extremely dangerous for commodity. Only hose, fittings, clamps and accessory items that have been approved for steam service should ever be used!. Never use an unapproved item for steam service. Always follow the manufacture’s product recommendations for pressurized steam handling

WARNING: Cancer and Reproductive Harm

| Weight | 1 kg |

|---|---|

| Hose ID | 1", 1 1/4", 1 1/2", 2", 2 1/2", 3" |

| Part Number | BU14, RBU14, BBU14, B14, RB14, B15, BU18, BU19, B19, RB19, BU22, B22, BU24, RBU24, B24, RB24, B25, BU28, BU29, RBU29, BBU29, B29, RB29, B30, BU34, B34, BU35, RBU35, B35, B39 |

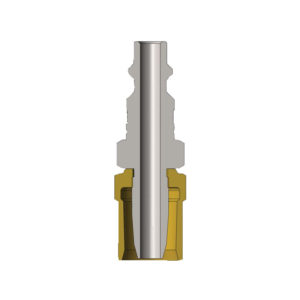

Be the first to review “Boss™ Clamp 4 Bolt Type, 2 Gripping Fingers” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.