The new and safe quick-release coupling system for the coupling and uncoupling of hose connection (also under pressure) where no medium is lost. Highly suitable for loading and unloading stations, bunker stations, coupling coupling panels, aircraft fueling, bottom-loading of road tankers and railway carriages and many other industrial applications. The standardised connection sizes mean the TODO coupling is interchangeable with e.g. Avery-Hardoll and Emco-Buckeye.

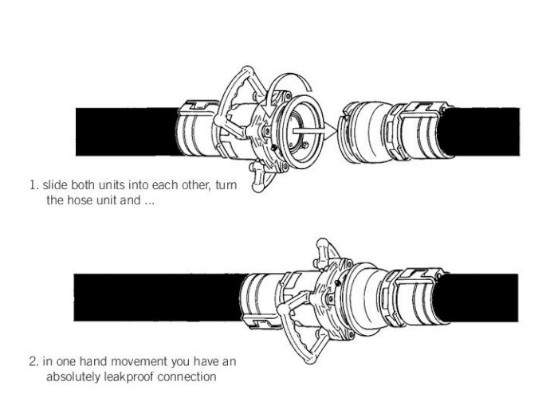

Operation and Construction

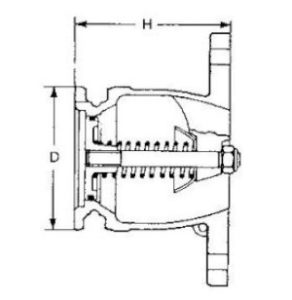

The coupling consists of hose unit with swivel part so it can be turned and fixed tank unit both with self-closing valve. The coupling is closed and locked by joining both parts and turning the hose approx. 15°. Turning further means both valves are simultaneously opened and the liquid released

With disconnection first both close both valves before the connection can be broken. The TODO coupling system in coupled and uncoupled state is suitable for a working pressure of 10 bar, while coupling or uncoupling to a pressure of 10 bar is possible (depending on the diameter).

To prevent soiling when uncoupled there is a plug for the hose unit and a cap for the tank unit

Material types

The availability of many material types for both coupling parts and the sealing rings means the TODO coupling is suitable for most chemical liquid and/or gases. As standard and the TODO coupling are built with Viton seals. It is therefore not surprising that the TODO coupling is approved by the TUV for the transport of hazardous substances (Approval number TUV AGG.052-86) and is already used by leading companies in chemistry and petrochemistry.

The Principle of TODO Coupling

Advantages of the TODO couplings:

- Fast and safe coupling and uncoupling, also under pressure

- Practically no medium loss with self-closing valves in both coupling halves

- Saves labour and the environment

- Simple to use with compact and robust construction

- Large capacity with little pressure loss

- Possibility of use with anti-mix selection system and position indication

- Interchangeable with other makes with international connection sizes

- TUV approved for hazardous substances

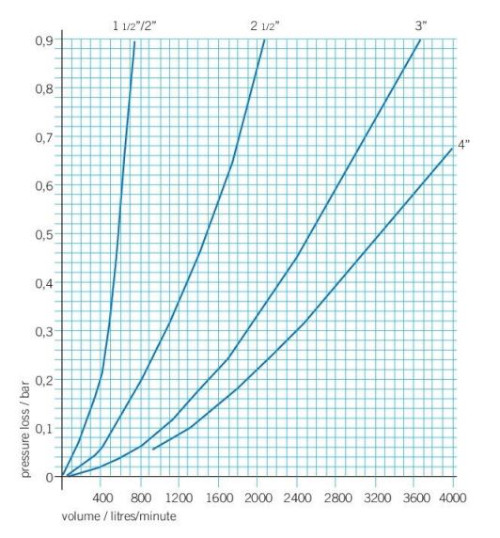

Pressure loss diagram

Test medium: gas oil

Density at 16°C : 0.795

Viscosity at 16°C : 1°E

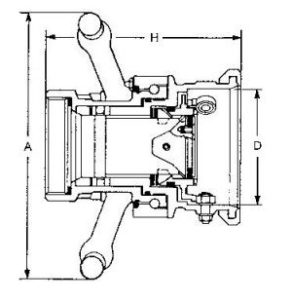

Main Size Hose Unit

| Nom ⌀ | A mm | H mm | Weight approx. kg | D (coupling size) mm | ||

| AL | MS | SS | ||||

| 1″ | 70 | 125 | 0,6 | 1,5 | 1,4 | 56 |

| 2″ | 175 | 164 | 1,2 | 2,8 | 2,5 | 70 |

| 2 1/2″ | 240 | 190 | 4,3 | 8,8 | 7,4 | 105 |

| 3″ | 260 | 190 | 4,9 | 10,2 | 8,8 | 119 |

| 4″ | 420 | 220 | 9,5 | 20,6 | 17,6 | 164 |

Material codes:

MS = Bronze

AL = Aluminium

SS = Stainless Steel 316

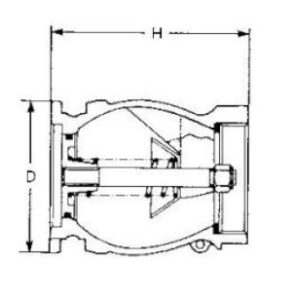

Main Sizes Tank Unit

| Nom ⌀ | D (coupling size) mm | H mm with thread | H mm with flange |

| 1″ | 56 | 77 | 75 |

| 2″ | 70 | 100 | 81 |

| 2 1/2″ | 105 | 134 | 112 |

| 3″ | 119 | 134 | 112 |

| 4″ | 164 | 162 | 140 |

Sizes and Materials

The TODO dry-break couplings are available in the sizes 1″, 2″, 2 1/2″, 3″ and 4″. Also available in all sizes types aluminium, bronze and stainless steel. As for standard the couplings are supplied with Viton sealing rings. Other qualities such as for example Nitrile, EPDM or Kalrez are also available. A catalogue with all TODO references is available

Connection Possibilities

The hose unit is supplied with an internal thread. As standard with BSP or NPT thread, but other types available upon request. The tank unit can be supplied with an internal thread or flange connection as required. BSP or NPT thread and DIN or ANSI flange as standard. Upon request other thread types (also male thread) or flange connections are available

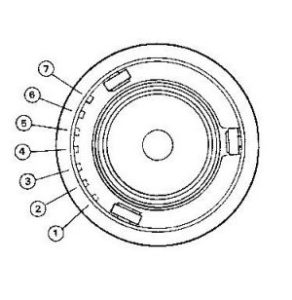

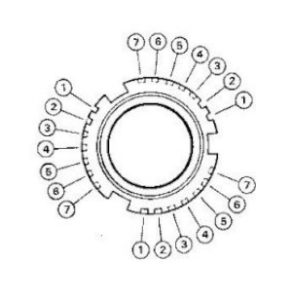

Selection System

To prevent the mixing or soiling of different media the TODO coupling ca be provided with a selection system. Then the use of pins in the hose unit and corresponding slots in the coupling flange of the tank unit provide coding per coupling. Twenty-one different variations per coupling possible

Position Indications

It is also possible to provide the TODO couplings with an electronic position indication system. It is then possible to see from a central point (e.g. control room) which hoses are in use and to which loading points they are connected. An extra connections can be supplied on the tank for sampling, air venting or drainage.

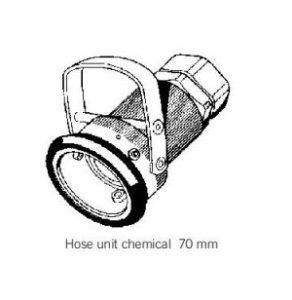

Chemical Design

This coupling was specially designed for non-self-lubricating products. The housing in stainless steel 316 and all other parts are manufactured using high quality materials. The pristin rod guide is coated in PTFE to guarantee the lowest possible friction resistance

Available in DN 25 (1″) – DN 50 (2″) and DN 80(3″0

With Viton® or Kalrez® seals (different compounds possible)

Chemical Design

| Coupling DN | Connection | Material | Seal | Weight | Code Hose Unit |

| 1″ – 56 mm | 1″ BSP | SS | Viton | 1.4 | 9102X-4407 |

| 1″ – 56 mm | 1″ BSP | SS | Kalrez 4079 | 1.4 | 9102X-4414 |

| 1″ – 56 mm | 1″ BSP | SS | Kalrez 2035 | 1.4 | 9102X-4434 |

| 1″ – 56 mm | 1″ BSP | SS | Kalrez 1050 LF | 1.4 | 9102X-4454 |

| 2″ – 70 mm | 2″ BSP | SS | Viton | 2.9 | 9200F-4407 |

| 2″ – 70 mm | 2″ BSP | SS | Kalrez 4079 | 2.9 | 9200F-4414 |

| 2″ – 70 mm | 2″ BSP | SS | Kalrez 2035 | 2.9 | 9200F-4434 |

| 2″ – 70 mm | 2″ BSP | SS | Kalrez 1050 LF | 2.9 | 9200F-4454 |

| 3″ – 119 mm | 3″ BSP | SS | Viton | 8.8 | 9300F-4407 |

| 3″ – 119 mm | 3″ BSP | SS | Kalrez 4079 | 8.8 | 9300F-4414 |

| 3″ – 119 mm | 3″ BSP | SS | Kalrez 2035 | 8.8 | 9300F-4434 |

| 3″ – 119 mm | 3″ BSP | SS | Kalrez 1050 LF | 8.8 | 9300F-4454 |

VITON® and KALREZ® are registered trademarks of DuPont Performance Elastomers

Material Codes:

SS = Stainless Steel 316

Thread Seal = PTFE

TODO-DRY BREAK couplings 1″-56 mm

| Coupling DN | Connection | Material | Seal | Weight Hose Unit | Weight Tank Unit | Code Hose Unit | Code Tank Unit |

| 1″ – 56 mm | 1″ BSP | AL | Viton | 0.6 | 0.2 | 7100-1407 | 4942-1107 |

| 1″ – 56 mm | 1″ BSP | GM | Viton | 1.5 | 0.7 | 7100-2407 | 4942-2207 |

| 1″ – 56 mm | 1″ BSP | SS | Viton | 1.4 | 0.6 | 7100-4407 | 4942-4407 |

| 1″ – 56 mm | 1″ BSP | SS | Kalrez 4079 | 1.4 | 0.6 | 7100-4414 | 4942-4414 |

| 1″ – 56 mm | 1″ NPT | AL | Viton | 0.7 | 0.3 | 7455-1407 | 7451-1107 |

| 1″ – 56 mm | 1″ NPT | GM | Viton | 1.6 | 0.8 | 7455-2407 | 7451-2207 |

| 1″ – 56 mm | 1″ NPT | SS | Viton | 1.5 | 0.7 | 7455-4407 | 7451-4407 |

| 1″ – 56 mm | 1″ NPT | SS | Kalrez 4079 | 1.5 | 0.7 | 7455-4414 | 7451-4414 |

| 1″ – 56 mm | 1 1/4″ BSP | AL | Viton | 0.6 | 0.2 | 7125-1407 | 4992-1107 |

| 1″ – 56 mm | 1 1/4″ BSP | GM | Viton | 1.6 | 0.6 | 7125-2407 | 4992-2207 |

| 1″ – 56 mm | 1 1/4″ BSP | SS | Viton | 1.5 | 0.5 | 7125-4407 | 4992-4407 |

| 1″ – 56 mm | 1 1/4″ BSP | SS | Kalrez 4079 | 1.5 | 0.5 | 7125-4414 | 4992-4414 |

| 1″ – 56 mm | 1 1/4″ NPT | AL | Viton | 0.7 | 0.3 | 7456-1407 | 7452-1107 |

| 1″ – 56 mm | 1 1/4″ NPT | GM | Viton | 1.7 | 0.7 | 7456-2407 | 7452-2207 |

| 1″ – 56 mm | 1 1/4″ NPT | SS | Viton | 1.6 | 0.6 | 7456-4407 | 7452-4407 |

| 1″ – 56 mm | 1 1/4″ NPT | SS | Kalrez 4079 | 1.6 | 0.6 | 7456-4414 | 7452-4414 |

| 1″ – 56 mm | 1 1/2″ BSP | AL | Viton | 0.7 | 0.3 | 7150-1407 | 4991-1107 |

| 1″ – 56 mm | 1 1/2″ BSP | GM | Viton | 1.8 | 0.7 | 7150-2407 | 4991-2207 |

| 1″ – 56 mm | 1 1/2″ BSP | SS | Viton | 1.7 | 0.6 | 7150-4407 | 4991-4407 |

| 1″ – 56 mm | 1 1/2″ BSP | SS | Kalrez 4079 | 1.7 | 0.6 | 7150-4414 | 4991-4414 |

| 1″ – 56 mm | 1 1/2″ NPT | AL | Viton | 0.8 | 0.4 | 7457-1407 | 7453-1107 |

| 1″ – 56 mm | 1 1/2″ NPT | GM | Viton | 1.9 | 0.8 | 7457-2407 | 7453-2207 |

| 1″ – 56 mm | 1 1/2″ NPT | SS | Viton | 1.8 | 0.7 | 7457-4407 | 7453-4407 |

| 1″ – 56 mm | 1 1/2″ NPT | SS | Kalrez 4079 | 1.8 | 0.7 | 7457-4414 | 7453-4414 |

TODO-DRY BREAK Coupling 2″ 70 mm

| Coupling DN | Connection | Material | Seal | Weight Hose Unit | Weight Tank Unit | Code Hose Unit | Code Tank Unit |

| 2″ – 70 mm | 1 1/2″ BSP | AL | Viton | 1.1 | 0.4 | 5005-1407 | 5001-1107 |

| 2″ – 70 mm | 1 1/2″ BSP | GM | Viton | 2.6 | 1.2 | 5005-2407 | 5001-2207 |

| 2″ – 70 mm | 1 1/2″ BSP | SS | Viton | 2.4 | 1 | 5505F-4407 | 5001-4407 |

| 2″ – 70 mm | 1 1/2″ BSP | SS | Kalrez 4079 | 2.4 | 1 | 5505F-4414 | 5001-4414 |

| 2″ – 70 mm | 1 1/2″ NPT | AL | Viton | 1.2 | 0.5 | 7468-1407 | 7466-1107 |

| 2″ – 70 mm | 1 1/2″ NPT | GM | Viton | 2.7 | 1.3 | 7468-2407 | 7466-2207 |

| 2″ – 70 mm | 1 1/2″ NPT | SS | Viton | 2.5 | 1.1 | 7468F-4407 | 7466-4407 |

| 2″ – 70 mm | 1 1/2″ NPT | SS | Kalrez 4079 | 2.5 | 1.1 | 7468F-4414 | 7466-4414 |

| 2″ – 70 mm | 2″ BSP | AL | Viton | 1.2 | 0.5 | 5006-1407 | 5002-1107 |

| 2″ – 70 mm | 2″ BSP | GM | Viton | 2.8 | 0.3 | 5006-2407 | 5002-2207 |

| 2″ – 70 mm | 2″ BSP | SS | Viton | 2.5 | 1.1 | 5006F-4407 | 5002-4407 |

| 2″ – 70 mm | 2″ BSP | SS | Kalrez 4079 | 2.5 | 1.1 | 5006F-4414 | 5002-4414 |

| 2″ – 70 mm | 2″ NPT | AL | Viton | 1.3 | 0.6 | 7469-1407 | 7467-1107 |

| 2″ – 70 mm | 2″ NPT | GM | Viton | 2.9 | 1.4 | 7469-2407 | 7467-2207 |

| 2″ – 70 mm | 2″ NPT | SS | Viton | 2.6 | 1.2 | 7469F-4407 | 7467-4407 |

| 2″ – 70 mm | 2″ NPT | SS | Kalrez 4079 | 2.6 | 1.2 | 7469F-4414 | 7467-4414 |

Material Codes:

AL = Aluminium , GM = Gunmetal , SS = Stainless Steel 316 , Thread Seal = AL + GM = VULKOLLAN , SS = PTFE

| Weight | 1 kg |

|---|

Be the first to review “TODO® Dry Break Coupling” Cancel reply

You must be logged in to post a review.

Reviews

There are no reviews yet.