About Shin-Yo Engineering

Shin-Yo is derived from the Japanese language and can be interpreted as ‘REPUTATION’, ‘TRUST’, and ‘KEEP PROMISES’. We strongly believe in prompt delivery to our customers to gain their trust and to establish and maintain our reputation. This is the foundation of the philosophy that we believe and practice in our company.

Established back in April 2000, Shin-Yo Engineering Sdn Bhd has a company history of over 25 years. Shin-Yo Engineering Sdn Bhd has grown over the years and at present day, has a workforce of over 60 employees.

Nature of Business

Shin-Yo Engineering Sdn Bhd is the sole distributor for various types of industrial hose, hose couplings, expansion joints, and mechanical products.

As an industrial tools supplier, we distribute all types of hoses including Flexible Hose, Hose Coupling, Ducting Hose, Rubber Hose, Industrial Hose, etc. With the application of our products we used, we are able to customize the coupling as per customer requirement.

Our Services

Hose Coupling Repair Services

More DetailsHOSE COUPLING REPAIR SERVICES

We are familiar with the flow of product from market need, product design, prototyping and development, field testing and production implementation. We are able to assist in covering these areas from start to finish with high quality components and wealth of experience in supporting your needs. We also provided the process of swaging, welding, clamping and cutting for hoses and coupling.

Vacuum Test Service

More DetailsVACUUM TEST SERVICE

The vacuum test is for testing of hose sections, which allows inspection of the inner surface of the hose for blisters or separation of the inner tube from the carcass. The process also carried out to detect an eventual delaminating of the rubber liner.

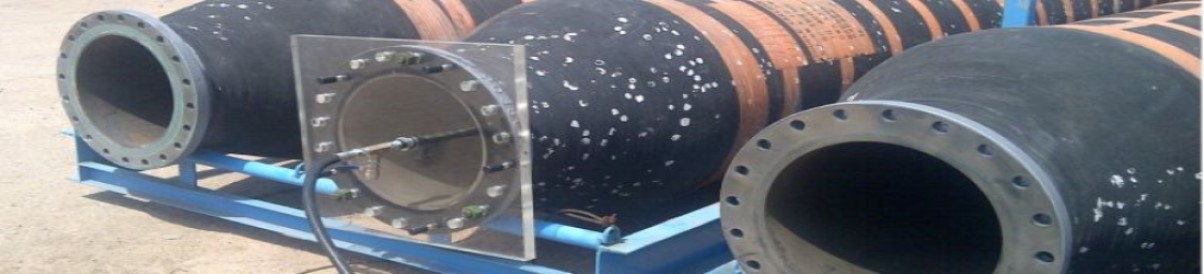

Hydrotest Services

More DetailsHYDROTEST SERVICES

A hydrostatic test is a way in which hose and couplings for pipelines, plumbing, gas cylinders, boilers and fuel tanks can be tested for strength and leaks. The test involves filling the equipment with a liquid, usually water, which may be dyed to aid in visual leak detection, and pressurization of the vessel to the specified test pressure. Pressure tightness can be tested by shutting off the supply valve and observing whether there is a pressure loss. The location of a leak can be visually identified more easily if the water contains a colorant. Strength is usually tested by measuring permanent deformation of the container. Hydrostatic testing is the most common method employed for testing pipes and pressure vessels. Using this test helps maintain safety standards and durability of an equipment over time. Newly manufactured pieces are initially qualified using the hydrostatic test. They are then re-qualified at regular intervals using the proof pressure test which is also called the modified hydrostatic test. Testing of equipment for transport and storage of gases is very important because such containers can explode if they fail under pressure.

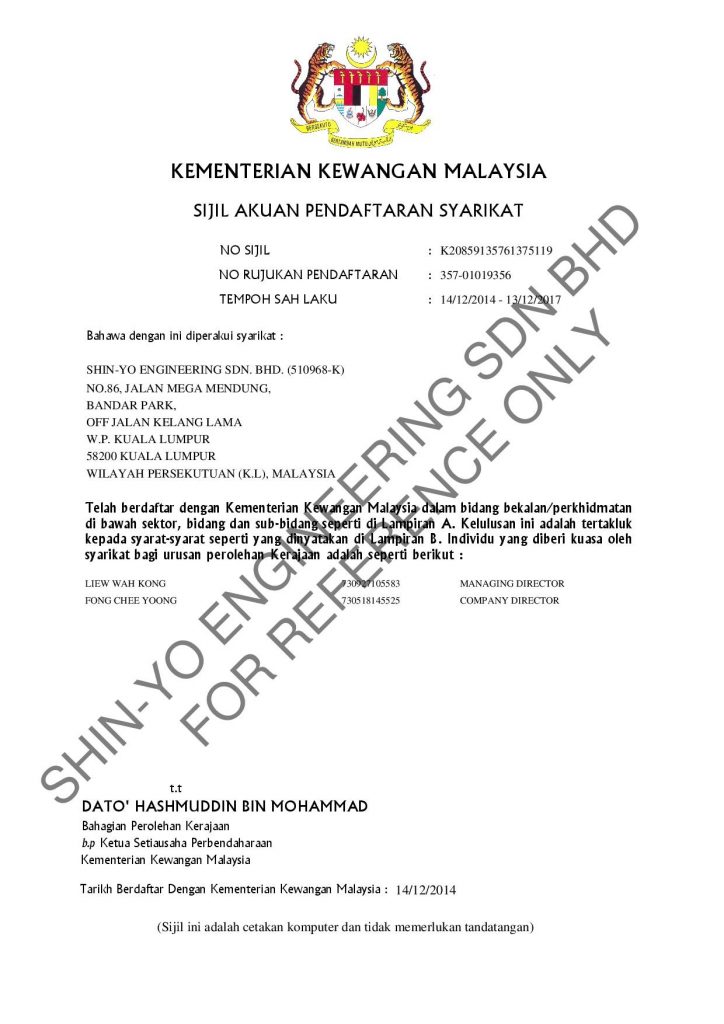

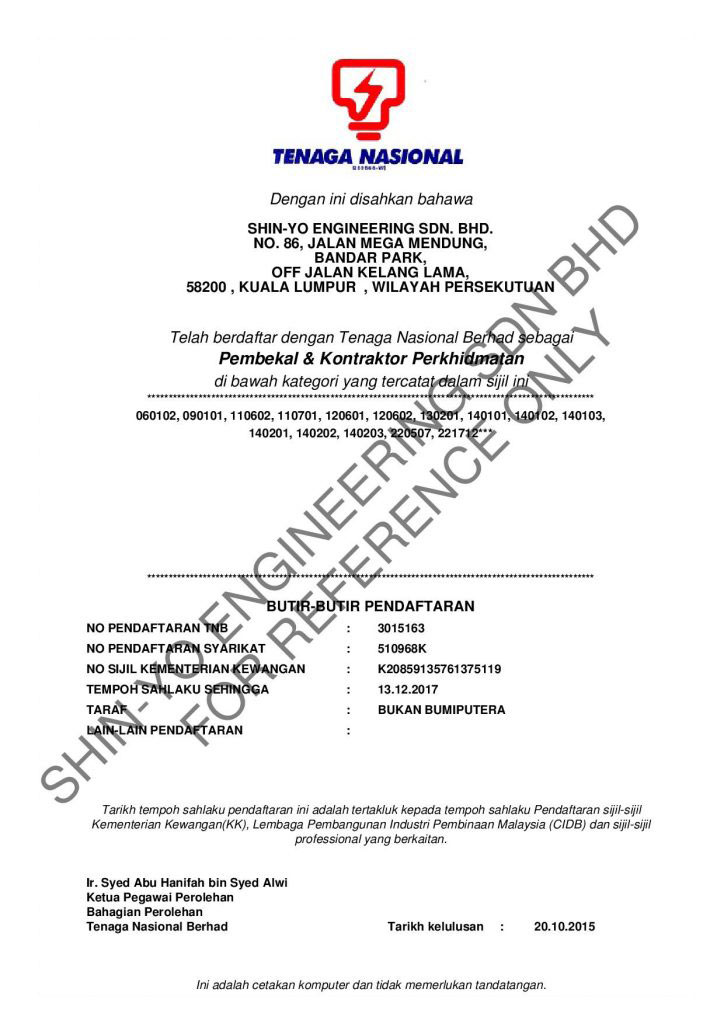

Our Certifications